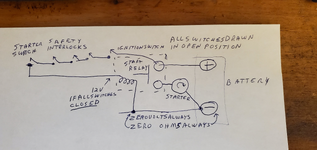

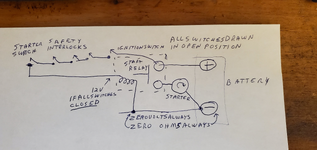

OK, I've got a minute. 1st thing for me is obtaining a wiring diagram. If you don't have the service manual, I'd strongly advise obtaining one; it's much easier to point out troubleshooting test points looking at the factory drawing. Lacking that at the moment, here's a 'generic' start circuit that should get you, uh, started. (sorry...)

Troubleshooting steps:

Volt-ohm meter & basic operating principles of same, obviously needed.

Black meter lead to battery negative *POST* (not any connector, bolt, etc; the actual post).

Red meter lead to battery positive post (see above).

power on, any interlocks that may exist, closed: press start button.

If starter turns, battery voltage should drop from ~12.5 V to (likely) somewhere between 9.5 & 11V, while starter is turning.

If starter doesn't turn, what's battery voltage while the button is pushed? If it remains at pre-button push levels, something in the start circuit is open or high resistance. If voltage drops to well under 9V, either the starter is shorted out or the battery is bad.

Assuming voltage stays at ~12.5V and you hear nothing or only a click, now we need to find the open/high resistance in the circuit.

Keep the black lead on the battery post throughout the following tests.

Move the red lead to the 'hot' side of the start relay coil (it will be a small terminal; not one of the 'fat' ones), press start. you should see 12v. If yes, continue; if no, you have a problem somewhere in the switch chain between battery + and the start relay coil 'hot' terminal.

Continuing.

If you do see 12v on the start relay coil, you should hear and feel the click of the relay. If no, move the meter probe to the negative terminal of the start relay (also small terminal) and press start again. You should see *ZERO* volts there, whether the start button is pushed or not. If you see any voltage there, there's a high resistance between the negative terminal of the relay and the battery negative terminal. Note that there could be interlocks in that ground path, instead of in the positive path to the relay coil.

If you see zero and you get the click, move the red probe to the 'hot Fat' terminal of the relay. Should see ~12.5v whether start is pressed or not. Press start, should hear click and if starter turns voltage should drop slightly (see above). If click and no starter turning, and voltage stays near 12.5v, then the contacts in the relay may be bad, but continue: move red probe to the other 'fat' terminal, press start, you should see same voltage as before. If zero or low volts, starter *might* be shorted (very unlikely) or as I said, the contacts in the relay are bad.

If voltage stays up near 12.5V, move red probe to the starter fat terminal, press start. Starter should turn and you should see 9.5-11V on the starter fat terminal. If it stays near 12.5v and starter doesn't turn, starter might be open, but we don't know yet (haven't checked ground path).

Move probe to the frame of the starter (may have to scratch through the paint somewhere, or get on a bolt and scratch through rust/corrosion to get a good connection). Press start and you should see ZERO volts. Anything higher than a couple of tenths of a volt indicates a broken or high resistance ground path back to the battery negative.

That's about all I can give you until you make the tests, but here's a tip on high-resistance type problems. They can be caused by corroded surfaces where a wire terminal attaches to its post (in either the postive circuit or the 'ground' (return) circuit. Corrosion can sometimes be hard to detect visually; you may need to wire-brush all mating surfaces until the metal is bright to be sure that corrosion is gone. But corrosion can also happen in the crimped area where the wire is inside a terminal. The shrink tubing that serves as a strain relief on many wire/terminal joints does a great job at hiding any corrosion, but even without the shrink tubing, it can be hard to detect. A good tug/twist on each wire is worth trying (check start function before/after each wire is tugged on) is a *sometimes* effective quick check. If you find one that makes a difference, you can play with the tug/twist to see if start function comes and goes as you wiggle the wire in its terminal.

Please respond both here and via PM once you've tried this stuff. I'm more likely to see a PM than the forum, with my rather hectic current (lack of) schedule.