Do not machine anything, chances are you are measuring it wrong and yes squish is very important. I have never seen one that couldn't be brought into spec. Make sure you are measuring directly over the piston pin, if the piston rocks at all your measurement will be off.

Group K deep dive.....

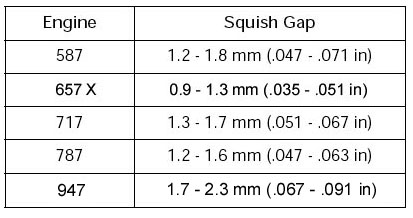

Precision Top End Assembly of the Laydown Rave Motors – Squish clearance, the distance between the piston crown and cylinder head at top dead center, is an important specification that is minded by the Rotax factory as well as all high performance engine builders. The Sea Doo manual offers a fairly wide tolerance for squish clearances, however most engine builders prefer closer clearances to help stave off detonation. Most builders measure the squish clearance by sticking a piece of solder through the spark plug hole toward the outside edge of the bore…then momentarily touching the start button so the piston makes several strikes at the solder. This allows the solder to be crushed to the exact thickness that shows the “squish clearance”. At Group K we make a point to take these “squish clearance ” measurements over both ends of the wrist pin. This minimizes the piston’s ability to “rock” and show an inaccurately large clearance. We also take these measurements over both ends of the wrist pin, on both cylinders, to assure uniform clearances. In a perfect world, all four squish measurement will be within .002″ – ,003″. Unfortunately, we have been observing everything but uniform clearances. This is a matter we do not take lightly, since accurate squish clearance is the only way to assure correct deck height setup (a function of the base gasket thickness).

Immediately, we though that the variations were caused by incorrectly cut squish bands on the cylinder head…not so. The bands had a uniform depth and perfect center to center location. We then suspected variations in the locations of the cylinder mounting holes in the crankcases, but they also measured perfectly. In the end, we found two items that caused the variations. The first was that the distance between the two cylinder bores can vary greatly, depending on the assembly procedure. That is, there can be almost 1 mm variation in the center to center distance of the bore diameters based solely on the random location during assembly. Secondly, the cylinder head itself has a great deal of movement leeway (both left to right, and forward to back). All these variations of fit take place because the cylinders and cylinder head are not located to one another with “dowel locating pins” (as most Kawasaki engines are). The absence of these locating pins allows for alot of movement leeway, of both the cylinders and the cylinder head. That results in broad variations in squish clearance measurements. Installing dowel pins is a questionably wise solution because of the great risk that the exhaust manifold faces would not be perfectly parallel (that would cause bore distortion when the exhaust manifold is torqued on).

For now, our best solution is to recommend a “Precision Assembly Procedure” that will make for minimum variations in squish measurements.

Our procedure is based on the following information. The cylinder base bolt patterns in the cases are located 132mm (5.196″) apart. The standard bore diameters of the cylinders are 82.0 – 82.08 mm (3.228″ – 3.231″). This means that the inner distance between the two bores of the torqued on cylinders should be between 49.91 – 49.98 mm (1.965″ – 1.968″) These last measurements can be taken quickly and easily with a set of dial calipers after the cylinders have been torqued on. In most cases, we have found that you can hit this spec range if you install the cylinders as close together as possible. It bears noting that we have seen engines where the water jackets of the cylinders touched before we could reach this specification range. We literally needed to belt sand some material off the aluminum cylinder casting to get the correct spec. Cylinders like this are certainly the exception (not the rule), but they do exist.

Once the cylinders are installed with the acceptable center to center distance, it becomes apparent that the cylinder head itself can move about 2mm (.080″ in any direction over the tops of the bores. This location will also have a profound effect on squish clearance measurements. We got out best results by matching the edge of the head casting, all the way around, as closely as possible to the edges of the cylinder castings. While this doesn’t sound very precise, it works surprisingly well. After torqueing on the head, you can take your four squish clearance measurements to determine if the head needs to be moved slightly one way or the other…it’s not really as tough as it sounds.

Does everyone one who assembles a Rave top end “have” to go through this whole procedure…not necessarily. However we strongly recommend this procedure to anyone preparing a high output Laydown Rave motor. If you find a wide variation in the squish clearances of your freshly assembled engine…it could certainly avert some problems before they get started.

Base Gasket Thickness – “Jon’s Story” – One of our early test boats was an XP that was to be raced in region one offshore. We shipped the kit to the owner, who had it assembled at a local shop. After the break-in, the test rider reported a little better top end, along with average bottom end power. We were concerned because all our other test riders had reported big increases in bottom end as well as peak rpm. After a few unsuccessful attempts to resolve the problem with carb tuning, he came to our shop with the machine. After a quick test ride, we found this XP to have mediocre acceleration and a 6900 rpm peak (that’s 150 rpm short of the norm). Back at the shop we checked out every possible problem. Besides the indicated compression being just a little low, the only other inconsistency was that the squish clearance seemed to be about .010″ (.25mm) too thick. At the time, we didn’t think this was the problem…but it was the only thing we saw that we could “fix”. We removed the .024″ (6 hole) base gasket and replaced it with a .016″ (4 hole) base gasket. The next morning we gave the boat a short break-in…then gassed it. The difference was unbelievable. The boat pulled viciously up to 7040 rpm…just like all our other test boats. No one was more shocked than us, that .008″ of base gasket thickness could turn a weakling into rocket. After this experience, we specified for our assembly instructions that a .038″ – .042″ squish clearance must be maintained on all Group K modified top ends. Since then, we have not experienced this problem again. (Note : This XP won the 90 minute 1200 pro overall at the Havasu Global Offshore Finals)