jimmaki

Active Member

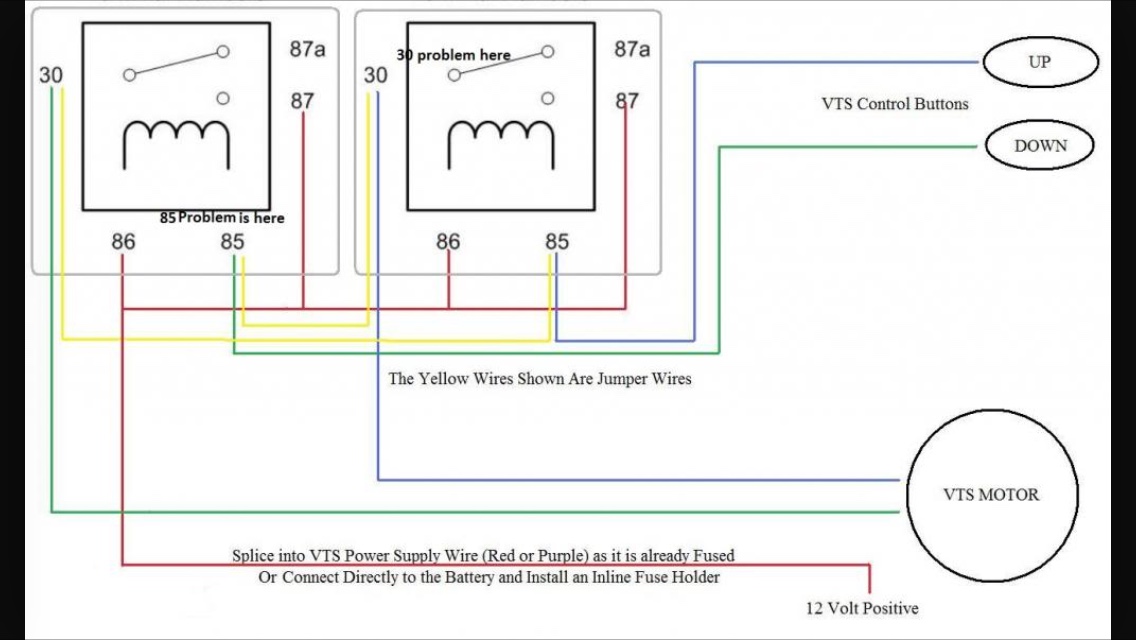

The VTS on my 98 SPX just quit working. When I press the up or down button, all I hear is a click coming from the VTS module. I opened the VTS oval motor box and found a lot of water corrosion inside. I disconnected the motor leads and jumped them straight to the battery and the motor appears to be working in both directions. So from what I gather the switches are working, the relay is working, and the motor works when connected directly to the motor. I assume the fuse is ok because of the clicking relay. I can't tell from the schematic if the fuse protects just the motor or all the power to the VTS module/motor.

If the motor is working is there benefit to taking it apart while I have it out? The round cover over the worm gear appears to be a metal cover that is crimped on. Not sure how to get it off and then how to secure it back on.

I'm thinking of drilling a hole in the bottom of the case to let water OUT as the box obviously isn't as sealed as the gasket and boot should appear to make it.

If the motor is working is there benefit to taking it apart while I have it out? The round cover over the worm gear appears to be a metal cover that is crimped on. Not sure how to get it off and then how to secure it back on.

I'm thinking of drilling a hole in the bottom of the case to let water OUT as the box obviously isn't as sealed as the gasket and boot should appear to make it.