Andrewdinsdale

Member

Hi guys,

This post rolls on from my last thread where I couldn't get my GSX running.

Now its had; a new ignition coil, 2 x carb repair kits plus 2 x new needle valves and seats & a solenoid.

Its finally running.

But when I try and start it, it will cough and splutter and not start, check the plugs and they're wet.

Turn the fuel off, and after 15-20secs of cranking it fires up, turn the fuel on and it runs lovely on the hose pipe for a good 10 minutes. Revs up, doesn't stall, idles fine (ready for a water test?) you'd think.

But stop it, try and start it and it won't start. Not until you turn the fuel off and crank it over for a good 20secs and it will fire up again.

Why would it be flooding if its had new needle valves and seats? + needle valve spring etc.

I think everyones going to say have you checked the pop off pressure but after doing hundreds of carbs previous to these if I put new needle valves and seats in they have never caused an issue. By the way, these were genuine 1.5 mikuni needle valves and seats.

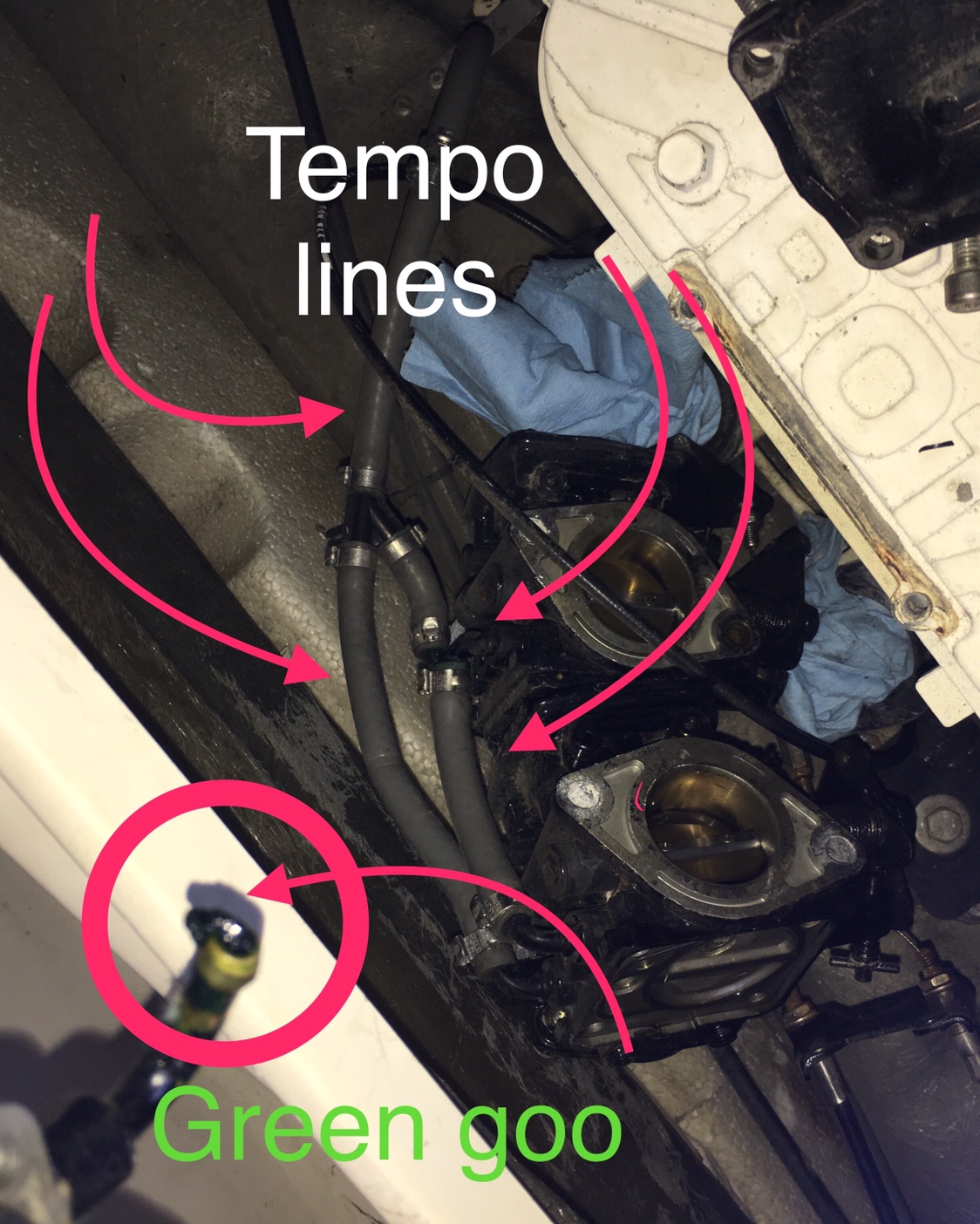

Only thing I have done that isn't standard is fitted a primer bulb off an outboard inline to help draw the fuel through the new fuel line that I installed. (My local seadoo dealer told me this was fine to do and fine to leave in). Is that right?

Any info appreciated. (Sorry for the length).

Thank-you.

This post rolls on from my last thread where I couldn't get my GSX running.

Now its had; a new ignition coil, 2 x carb repair kits plus 2 x new needle valves and seats & a solenoid.

Its finally running.

But when I try and start it, it will cough and splutter and not start, check the plugs and they're wet.

Turn the fuel off, and after 15-20secs of cranking it fires up, turn the fuel on and it runs lovely on the hose pipe for a good 10 minutes. Revs up, doesn't stall, idles fine (ready for a water test?) you'd think.

But stop it, try and start it and it won't start. Not until you turn the fuel off and crank it over for a good 20secs and it will fire up again.

Why would it be flooding if its had new needle valves and seats? + needle valve spring etc.

I think everyones going to say have you checked the pop off pressure but after doing hundreds of carbs previous to these if I put new needle valves and seats in they have never caused an issue. By the way, these were genuine 1.5 mikuni needle valves and seats.

Only thing I have done that isn't standard is fitted a primer bulb off an outboard inline to help draw the fuel through the new fuel line that I installed. (My local seadoo dealer told me this was fine to do and fine to leave in). Is that right?

Any info appreciated. (Sorry for the length).

Thank-you.