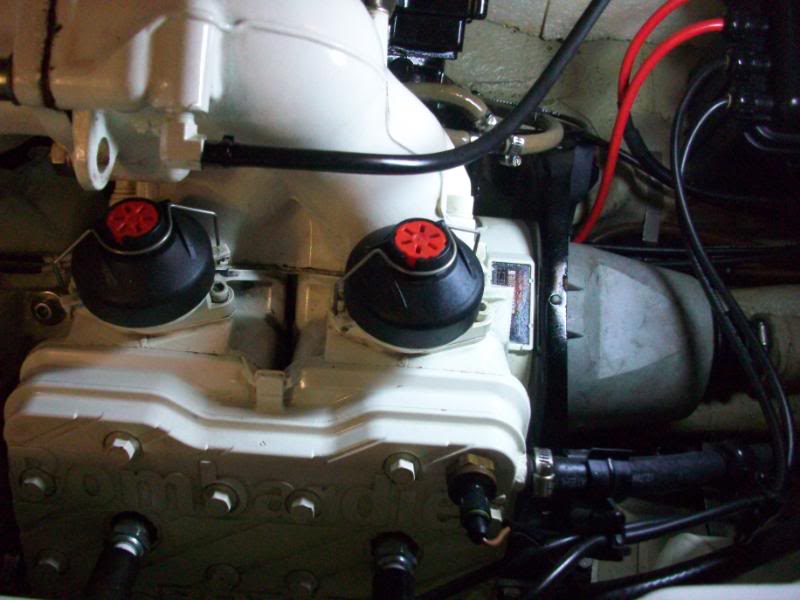

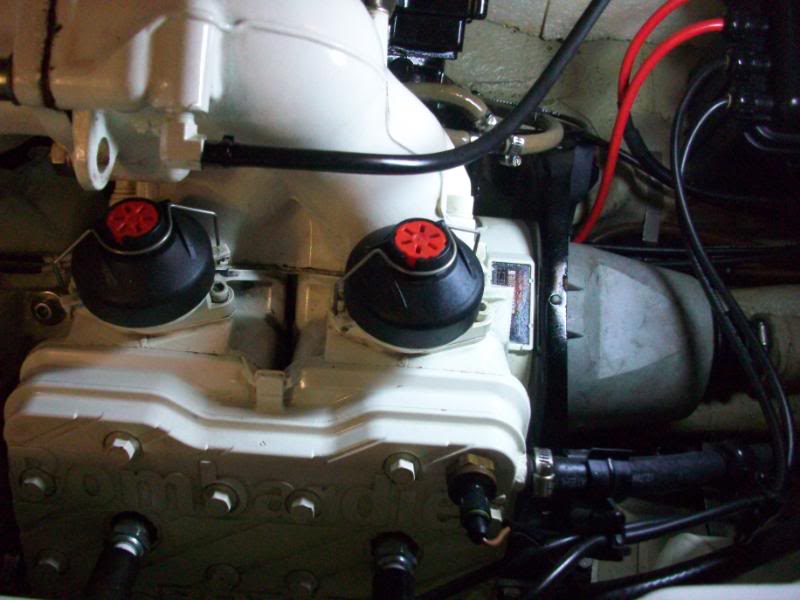

OK I know there is a million threads on how to do this...but I was bored. I see alto of people still nervous on servicing these even after reading on how to do them. (even I was)....but after I did them, I thought to myself that was way easier then I thought it would be....So I thought I would put up some pics on how to do them so people can see just how easy it is.

This is pretty messy so I would def recommend using some latex gloves....took me forever to get it off my hands. I'm sure there is several ways to do this, but this is how I did it. If I missed something please chime in

Start by removing the clip that holds on the cap

Pull the cap off but be sure not to loose the spring under it

Now unscrew the piece under the cap...you may need a 10mm socket to loosen it

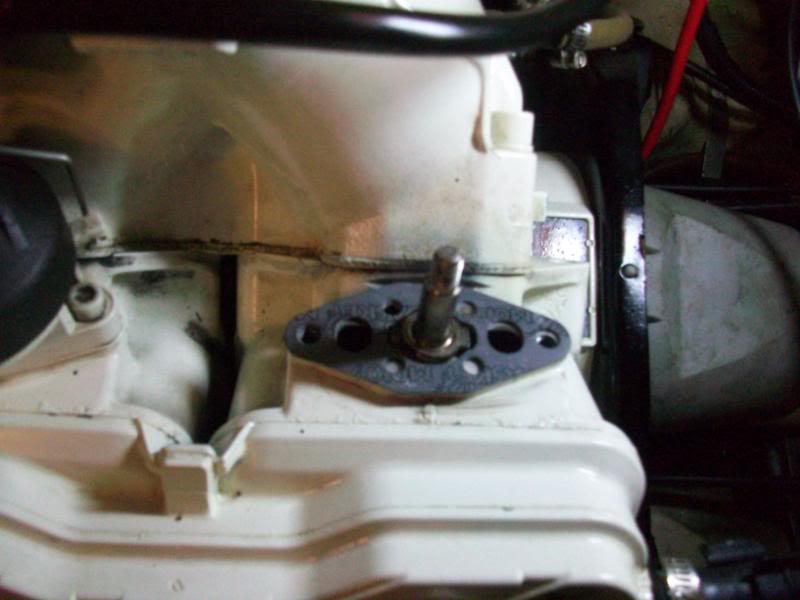

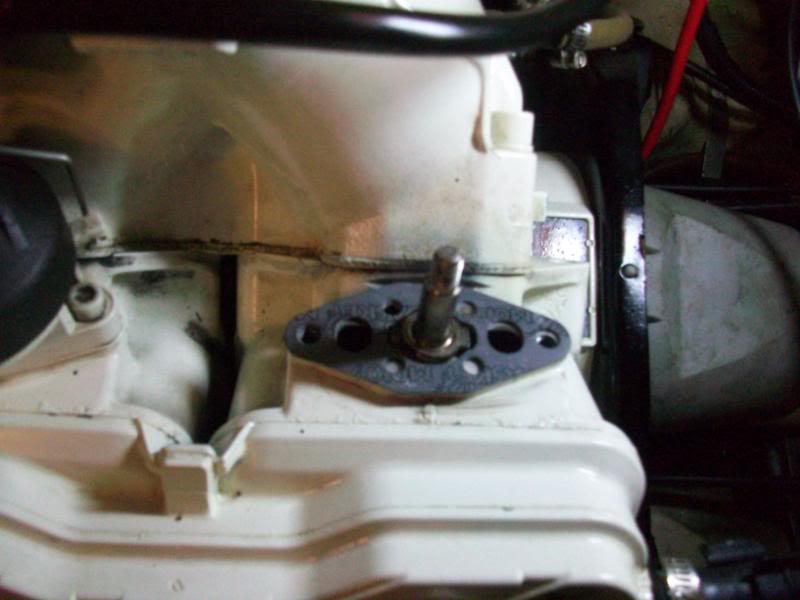

Now take a #5 hex to take the 2 screws out

Remove the base....if the whole valve comes out with it just pull them apart after you get it out

Now slide the valve out

Now clean the valve with a wire wheel...and I used some brake clean too

Should look about like this when done

I put a new gasket on as well

Now just reinstall everything and your done

This is pretty messy so I would def recommend using some latex gloves....took me forever to get it off my hands. I'm sure there is several ways to do this, but this is how I did it. If I missed something please chime in

Start by removing the clip that holds on the cap

Pull the cap off but be sure not to loose the spring under it

Now unscrew the piece under the cap...you may need a 10mm socket to loosen it

Now take a #5 hex to take the 2 screws out

Remove the base....if the whole valve comes out with it just pull them apart after you get it out

Now slide the valve out

Now clean the valve with a wire wheel...and I used some brake clean too

Should look about like this when done

I put a new gasket on as well

Now just reinstall everything and your done