Guys, I'm asking for your input(s) with words and pictures.

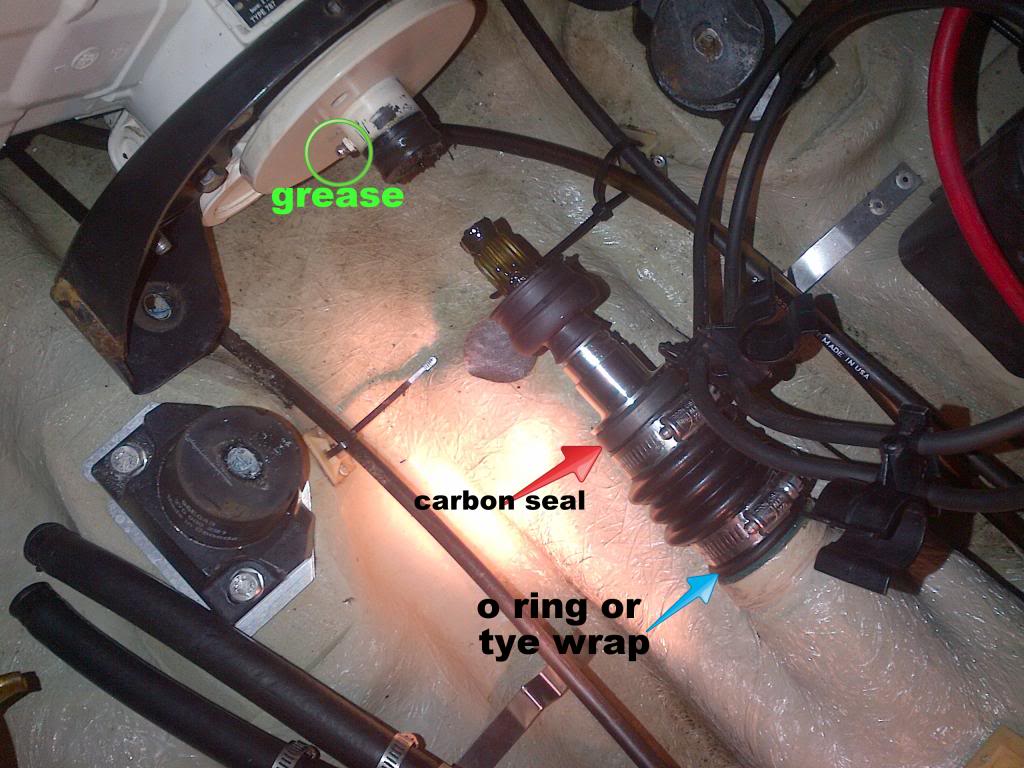

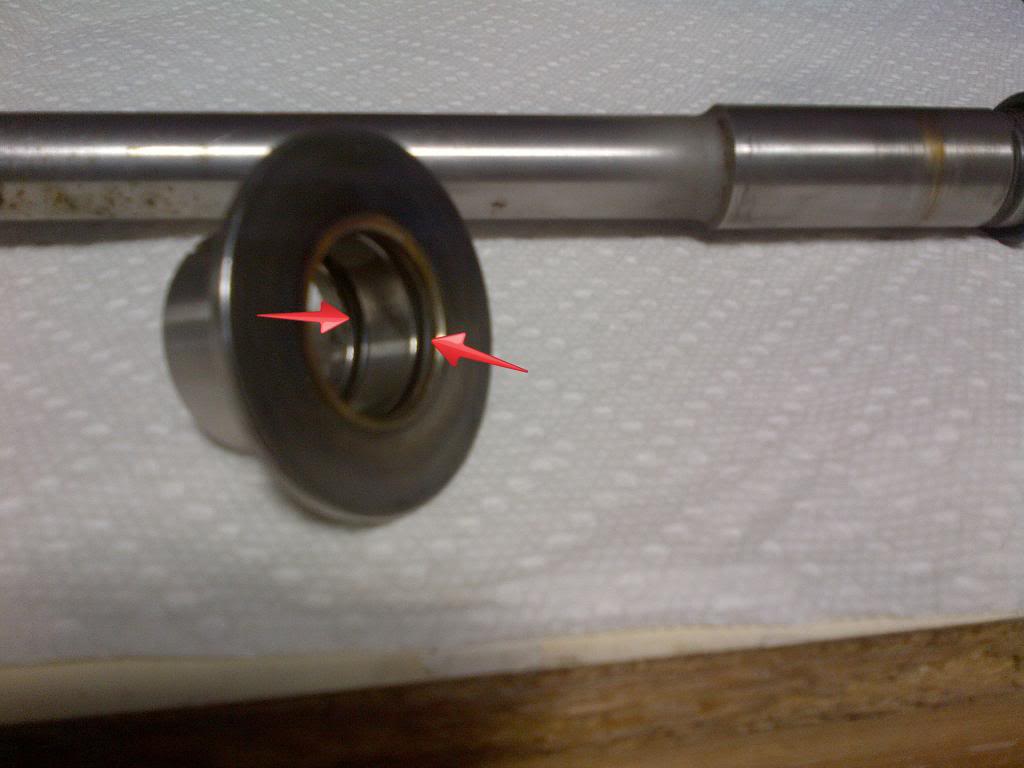

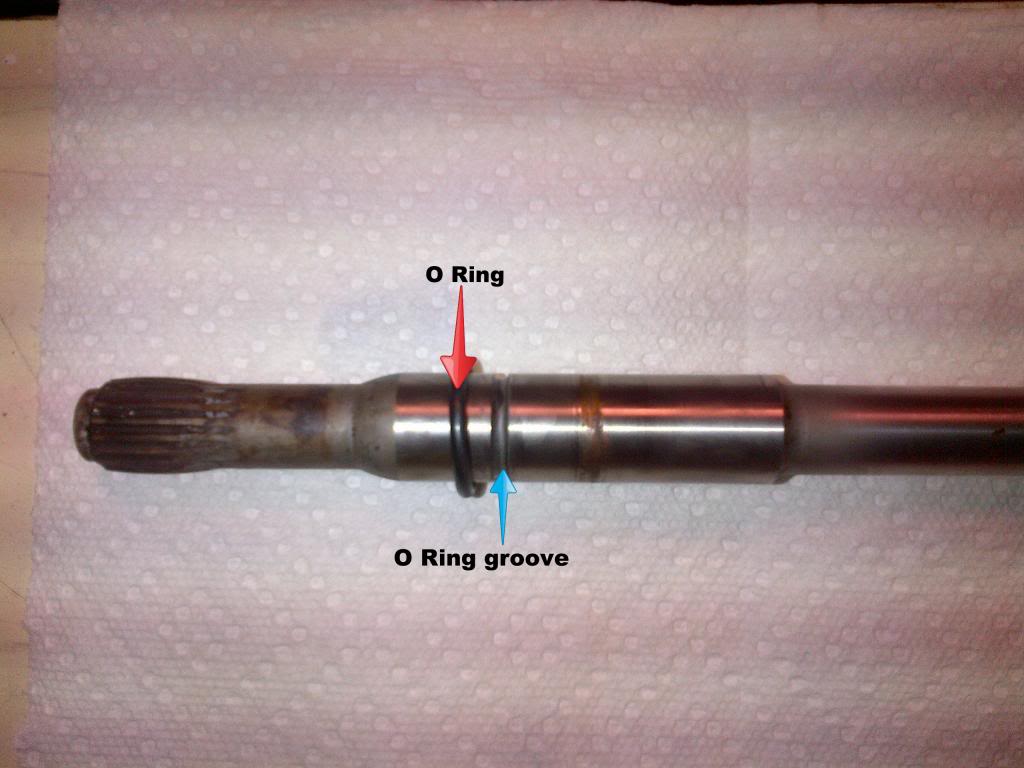

For some reason we have seen a rash of carbon seal failures this summer. I'm not sure why. It occurred to me that we really need a "How-To" article on the subject. Personally I have never changed one, I've been lucky I guess. I do know how its done because I've removed the drive shaft a time or two.

Anyway if you guys could put together a thread I think it would be a real asset, just do it in the 2-stroke section and I'll move it to the How-To section. I'm going to alert guys who are active and who would have the knowledge and pictures to do this, so if your name is not here please feel free to contribute. Lets try to keep this mostly answers with few questions. Thanks guys.

[MENTION=16022]Dr Honda[/MENTION] [MENTION=59978]kicker[/MENTION] [MENTION=57920]racerxxx[/MENTION] [MENTION=41828]Minnetonka4me[/MENTION]

Lou

For some reason we have seen a rash of carbon seal failures this summer. I'm not sure why. It occurred to me that we really need a "How-To" article on the subject. Personally I have never changed one, I've been lucky I guess. I do know how its done because I've removed the drive shaft a time or two.

Anyway if you guys could put together a thread I think it would be a real asset, just do it in the 2-stroke section and I'll move it to the How-To section. I'm going to alert guys who are active and who would have the knowledge and pictures to do this, so if your name is not here please feel free to contribute. Lets try to keep this mostly answers with few questions. Thanks guys.

[MENTION=16022]Dr Honda[/MENTION] [MENTION=59978]kicker[/MENTION] [MENTION=57920]racerxxx[/MENTION] [MENTION=41828]Minnetonka4me[/MENTION]

Lou

Last edited by a moderator: