Finally got back home after being away most of the Summer.

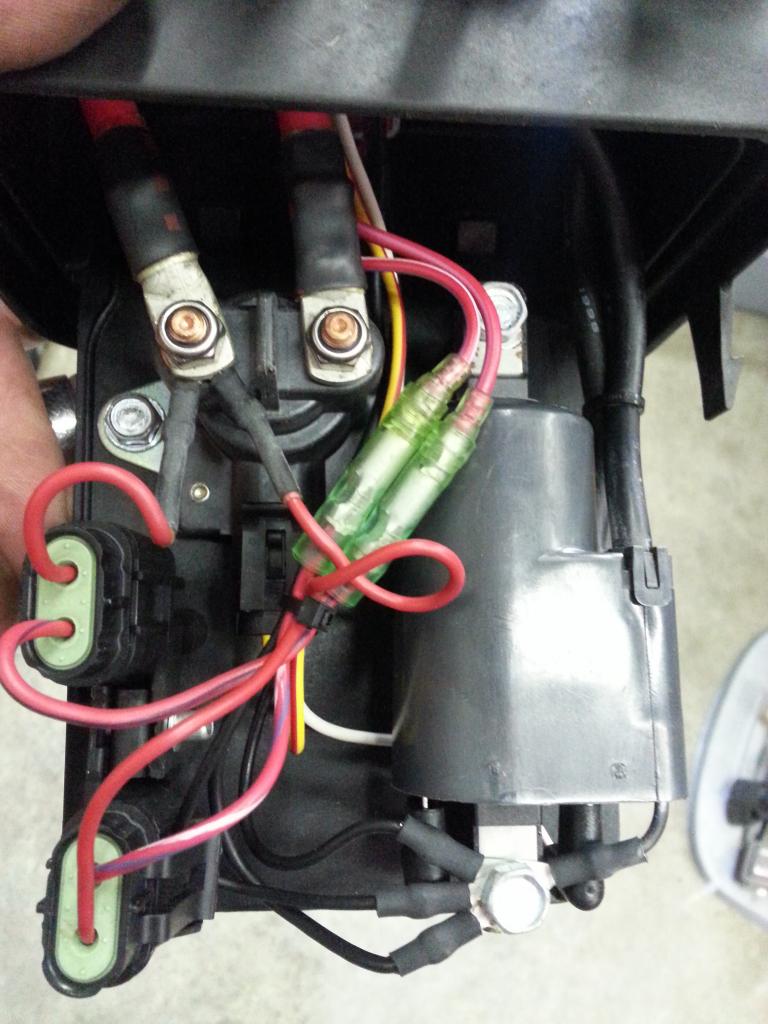

I took your advice and concentrated on the wiring. Replaced the main ground, both large red cables. Then I pulled out the cable connector from the top of the ignition relay box and disassembled it. The crimp on the small black wire that goes to the battery was bright green. The white wire (the one that carries the trigger signal from the pickup above the stator) was also extremely corroded.

So I cut the wires from all six pins and began stripping them back until I got to shiny copper strands. The black wire was oxidized black under the insulation so I replaced the entire wire. The white wire wasn't as simple because it runs all the way forward to the CDI module. That particular wire was oxidized back at least a foot so I replaced it as well.

Six new female pins, a new female connector housing, two battery cables, a starter cable for a grand total of around $20US. Beep, beep...then vroom!

Thanks for the advice and for keeping me on task to track this problem down.

As a side note, I met a gentleman while I was away in the Atlanta area who hooked me up with some plastic parts for my XP. He told me that, in the 20 years he has worked on these machines, 90% of the problems have turned out to be electrical and most of them could be fixed by cleaning corrosion off the connector pins.

Sounds plausible.

Here's a shot of the new (to me) XP ready to go back into the water. Gotta make the best of what's left of Summer.