You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1996 xp bogging on low rpm but runs fine on high rpm

- Thread starter rubves

- Start date

-

- Tags

- bogging stalling xp 1996

- Status

- Not open for further replies.

Your pilots are below the carb, and will have a T on top of the screw. The highs have nothing other than a slot, and are on the top of the carb, (sometimes there is a plastic cap on top of the high speeds), usually they are set between Zero and 1/4 out from the factory, UNLESS the ski has been modified. If you have trouble getting at the pilots, remove the air box and that will give you easier access.

When a ski stalls from out of the hole, (and that I can feather/pump ) it up to high speed, usually, it is my experience, that the pop off is too high.

When a ski stalls from out of the hole, (and that I can feather/pump ) it up to high speed, usually, it is my experience, that the pop off is too high.

It's super way easier to turn those screws, then checking pop off, (you have to remove the carbs, disassemble them, get or make a pop off gauge, find the thread,etc..)...first, turn the screw in till it is seated, keeping track of how many turns, it will be about 1 or so full turns, you can google the exact number. Then turn out the screw 1/4 turns out more. And of course do the same to the other one.

Either way, this is a temporary fix, since it indicates your carb is not getting its stock factory setting, and that you need to go thru the carbs. (Or fuel delivery system starting at the fuel pick up ).Hope this helps you get started,

Either way, this is a temporary fix, since it indicates your carb is not getting its stock factory setting, and that you need to go thru the carbs. (Or fuel delivery system starting at the fuel pick up ).Hope this helps you get started,

Screw all the way in first, count the turns, look up the factory setting, see if they match, for a base line, then add 1/4 turn out, which is a lot for the pilot, usually you make adjustments of 1/8 turn of a turn...the pilot is very sensitive to opening or closing, if the pilot is at factory, then try that first, no adjustment, , if not, go to factory and add 1/4 turn.

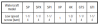

mine should be 1 turn out, does this look right?

source: http://seadoomanuals.net/download/pdf/service/manuals/1996/1996-seadoo-service-shop-manual.pdf

source: http://seadoomanuals.net/download/pdf/service/manuals/1996/1996-seadoo-service-shop-manual.pdf

R-u-n2it

Active Member

If the engine has ever had water in it the fuel pump can be damaged and not able to build enough pressure to blow the pop-off, or if air box was replaced with flame arrestors you will have less manifold vacuum at higher rpm, and manifold vacuum is what draws fuel through all the different delivery ports and along with alternating lower end pressure drives the fuel pump. Popps knows what's up. Back in the 2 stroke World Finals days guys would tune with radar and didn't understand why it would hesitate hitting throttle exiting a corner, the fix was open low speed (idle fuel screw that affects throttle off idle tapering off between 1/8th-1/4 throttle) and caused from throttle chop entering corner which pulls the boundary layer of fuel coating all the bottom end surfaces and so exiting nailing throttle makes manifold vacuum drop and fuel that's needed for correct power ratio is lean due to it condensing back onto bottom end surfaces, so a rich idle mixture allows extra fuel when throttle chopped to help keep the bottom end saturated. Yeah, no idling for long periods through no wake zone so just blip the throttle now and then and lean when stabbing the throttle under max engine loading isn't the recipe for engine longetivity but quickly adding heat to the piston will accelerate engine wear. Without high tech fuel injection that measures every possible parameter carbs are a series of compromises but no software/computer needed to tune once you understand the process. Sorry for the term paper. Lee

Carburetor pop-off pressure????

"1) Pop-off pressure is the pressure that takes to force open the needle, to allow fuel to flow into the carb. The pressure is equivalent to the float bowl hight in a conventional carb. It is mostly a tuning tool for low, to low/mid fuel flow... but if the pressure is too high, it can cause other problems, and you can melt your engine because it could cause a lean run." -Dr. Honda

35 should be fine. I am sure someone will tell me I am wrong, but I have always aimed for the middle of the road on the pop-off pressure recommended by seadoo.

My assumption being: if the pressure is too high then you risk running lean so if it is too low then you "risk" running rich which is never that big of a concern (aside from fouling plugs which is a lot cheaper of a mishap then a seized piston). However, if you're running too low then you will run into issues such as the one you described in the original post.

All in all if you're within the factory spec for the pop-off pressure you should be able to adjust the low-speed needles to compensate in either direction.

"1) Pop-off pressure is the pressure that takes to force open the needle, to allow fuel to flow into the carb. The pressure is equivalent to the float bowl hight in a conventional carb. It is mostly a tuning tool for low, to low/mid fuel flow... but if the pressure is too high, it can cause other problems, and you can melt your engine because it could cause a lean run." -Dr. Honda

35 should be fine. I am sure someone will tell me I am wrong, but I have always aimed for the middle of the road on the pop-off pressure recommended by seadoo.

My assumption being: if the pressure is too high then you risk running lean so if it is too low then you "risk" running rich which is never that big of a concern (aside from fouling plugs which is a lot cheaper of a mishap then a seized piston). However, if you're running too low then you will run into issues such as the one you described in the original post.

All in all if you're within the factory spec for the pop-off pressure you should be able to adjust the low-speed needles to compensate in either direction.

Last edited:

well im 3psi higher than the middle so if i lower it a little i will be completely in the middle of the recommendation from seadoo. but Dr. Honda do have a point with the spring strenght, so i think i will be okay by running it like it is for now while i wait for the new 80grams springs. better to be a little rich than lean, atleast thats what ive heard. so if i go 30psi i think it will work out for now

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 947

- Replies

- 15

- Views

- 821